AMT: Trusted Medical Device Contract Manufacturing.

For about 85% of medical device startups, finding a trustworthy manufacturing partner is critical. This heavily influences on-time market entry.

AMT Pte Ltd, based in Singapore, focuses on contract manufacturing. With years of https://amt-mat.com/a-deep-dive-into-contract-manufacturing-of-medical-devices/ experience, AMT provides full-spectrum medical device manufacturing services. AMT manages everything—from materials sourcing and rapid prototyping to precision assembly and market launch.

AMT’s ISO 9001 and ISO 13485 certifications support compliance for U.S. and EU exports. This focus on compliance lowers risks for OEMs and enables faster regulatory submissions.

Medical device OEMs, startups, and product teams regard AMT essential. AMT helps simplify production, cut costs, and accelerate time-to-market. Companies can scale capacity with AMT while maintaining design control and secure IP protection.

Core Lessons

- AMT contract manufacturing blends OEM know-how with end-to-end production services.

- Robust credentials include ISO 9001, ISO 13485, plus alignment to 21 CFR Part 820.

- Services cover procurement, prototyping, assembly, and final release for global markets.

- Outsourcing to AMT lowers capital expenditure and speeds up development timelines.

- Targeted at medical device OEMs, startups, and product teams seeking trustworthy partners in Singapore.

Medical Device Market Outlook and Growing Need for Contract Manufacturing

The global demand for medical technology is rising quickly. Experts believe the market will be worth more than $595+ billion by 2024 and might even reach $625 billion by 2027, expanding at ~6% annually through 2030.

This growth drives a significant need for scalable production, more products, and strict quality from partners who provide top-notch medical device manufacturing services.

Advances in cardiac, orthopedic, neuro, urology, and diabetes tech are fueling product surges. Because these categories require precision parts, electronics, and sterilizable items, many device makers are outsourcing.

They do this to tap specific tooling, automated processes, and inspection systems without spending a lot of money.

By outsourcing, companies can accelerate launches. With facilities, cleanrooms, and expertise, contract manufacturers compress design-to-launch timelines. For items like remote-controlled devices or online health monitors, partnerships are key to making complex devices widely available.

Singapore is a top spot for medical device suppliers and shipping operations. It has talented engineers, aligns with global rules closely, and is near many Asian markets. This makes Singapore great for contract manufacturing of medical devices by companies like AMT, supporting both small and large orders well.

As makers of medical devices focus more on their core competencies, they look for the best contract manufacturing partners to lower risks and speed up product launches. Singapore partnerships combine domain expertise, robust supply chains, and deep manufacturing to deliver complex products worldwide.

Why OEMs Choose Medical Device Contract Manufacturing

Original equipment manufacturers (OEMs) partner with specialists as production needs grow to keep focus on designing the product, regulatory strategy, and market entry, while experienced teams handle manufacturing—a strong fit for innovating under strict quality.

Keep Focus on R&D, Market & Regulatory Strategy

When OEMs let engineers focus on R&D and regulatory planning, outcomes improve. By outsourcing production, they can reallocate effort to testing, labeling strategy, and market outreach. With AMT, design changes stay traceable and audit-ready.

Avoid CapEx & Enable Scalable Production

Smaller companies face high equipment and cleanroom costs; teaming with AMT for custom medical device manufacturing avoids these big expenses. AMT has the infrastructure ready, enabling quick prototypes or full production without buying expensive equipment.

Faster time-to-market and rapid prototyping advantages

In competitive fields, speed is key—telehealth devices and wearable pumps need rapid development. With AMT, rapid prototyping/testing/transfer shortens development and speeds approvals.

| OEM Need | What AMT Provides | Benefit to OEM |

|---|---|---|

| Regulatory documentation | ISO-aligned QMS with validation support | Smoother audits, faster approvals |

| Prototyping and iteration | Rapid tooling, electronics integration, and small-batch runs | Faster cycles, reduced time-to-market |

| Scale-up to production | Automated assembly lines and validated processes | Predictable lead times, lower unit cost |

| Cost management | Lean manufacturing and supply-chain management | Lower CapEx, improved margins |

| Specialized builds | Custom manufacturing for disposable and electronic devices | Access to multidisciplinary expertise without hiring |

Partnering with AMT transforms development via expertise, equipment, and quality systems, enabling faster patient access—smart for growth-focused companies.

contract manufacturing of medical devices by AMT

AMT delivers a complete service from prototype to production; clients get single-point accountability with AMT as OEM and contract partner—simplifying buying, building, and shipping complex devices.

AMT handles full assembly contracts and customizes production to client needs, offering rapid prototyping, commercialization planning, and ramp-up—each step traceable to accelerate updates and reduce market-entry risk.

Full assembly under an end-to-end service model

AMT engineers co-develop DFM with OEM teams to cut rework, shorten builds, and improve output while handling sourcing, QC, and assembly.

ISO 9001/13485 & 21 CFR 820 Compliance

Operations rest on strong quality systems—ISO 9001 and ISO 13485 certified—and follow 21 CFR Part 820, helping ensure audit-ready devices for global markets.

Cleanrooms, tooling & automation at AMT

Cleanrooms, advanced tooling, and automation reduce errors and ensure traceability for sterilization and cleanliness needs.

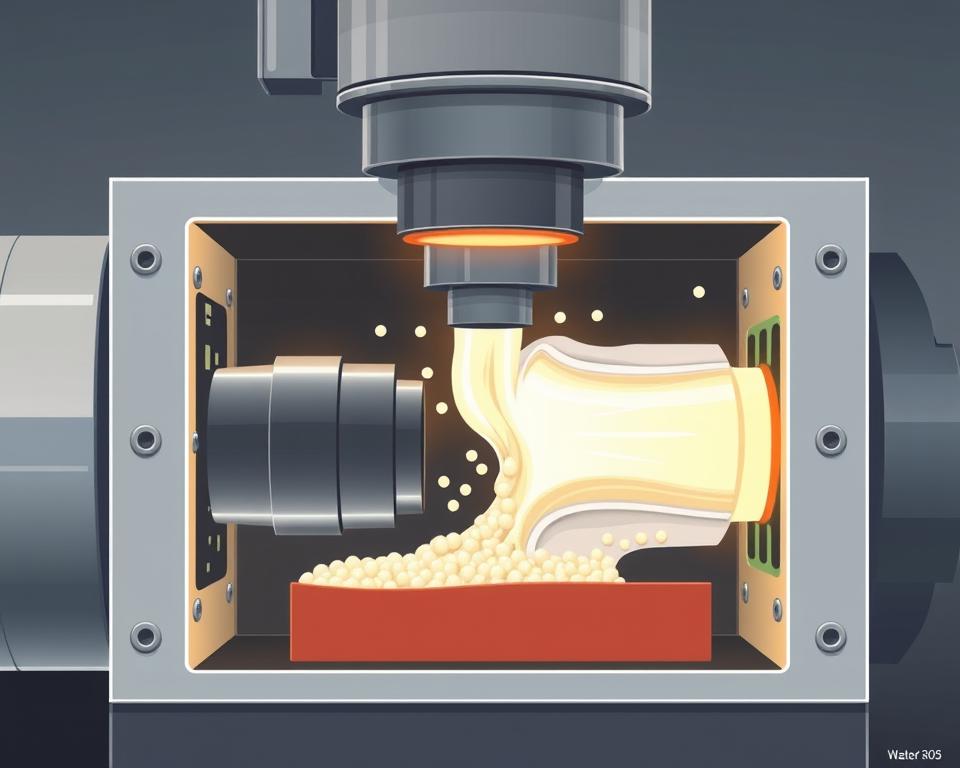

Core Capabilities: Injection Molding, PCBA, Precision Assembly

Advanced methods allow AMT to serve low/high volumes consistently for hospital, clinic, and home-care needs.

Injection molding produces strong, sterilizable parts ideal for medical use—housings, brackets, adapters—reducing cost while meeting strict cleanliness standards.

Printed circuit board assembly (PCBA) is critical for modern medical electronics; AMT builds heart monitors, wearables, and telehealth modules with controlled soldering and full traceability, enabling complex devices.

Precision assembly brings together mechanical parts and electronics into dependable products; expert technicians and strict inspections ensure high quality using approved materials and components.

Supply chain management keeps risks low and tracks every part—lot tracking and supplier checks ensure standards are met, enabling reliable, compliant devices.

Compliance, Quality Systems, and Risk Control

AMT’s quality aligns to ISO 9001/13485 and 21 CFR 820, using gated checks across design/production/release to cut risk and build confidence.

QMS aligned with FDA & ISO

AMT keeps detailed procedures, strict work instructions, and robust training; internal audits, supplier checks, and management reviews maintain adherence, reducing errors and supporting multi-region regulatory documentation.

V&V, Design Transfer, and Documentation

AMT seamlessly connects OEM engineering with factory scale-up, verifying and validating designs to confirm performance; detailed records and DHFs simplify submissions and support lifecycle maintenance.

Supply Chain Risk & Traceability

AVL management with serial/lot control prevents issues and protects integrity through supply fluctuations.

An experienced CM such as AMT ensures quality, compliance, and risk control end-to-end.

Case Studies & Success Stories Showing AMT Expertise

AMT’s respiratory and telehealth programs demonstrate faster development, quality assurance, and regulatory success across regions.

Ventilator Telehealth Project and Remote Ops

As a Tier-2 supplier, AMT played a vital role in the first telehealth ventilator supporting manual and remote control—cutting PPE use and allowing one clinician to monitor many patients from a single station—showcasing expertise in connected-care devices.

Assisted cough machines and respiratory therapy device examples

AMT built systems for high-frequency chest vibrations, lung expansion, and cough assistance, maintaining airway patency with Positive Airway Pressure during breaks and using clean air-path control—requiring exact PCBA, precise molded fluid paths, and clean packaging—proving leadership in respiratory devices.

Disposable Surgical Components: TURP Electrodes

Sterile single-use TURP electrodes (steel/tungsten) require strict material control and traceability—AMT’s strength in disposables.

Learning transfer speeds innovation—ventilator/respiratory lessons inform wearables and surgical tools—another reason to partner with AMT for faster scale.

Cost, Timeline & Commercial Benefits with AMT

Working with AMT lowers upfront costs by avoiding cleanrooms and machinery, redirecting funds to design and market entry.

AMT saves on components via purchasing power; skilled sourcing obtains quality parts at better prices, helping competitive retail and clinical pricing.

Automation with rapid prototyping speeds transition to production, helping hit clinical and regulatory milestones earlier.

Timing is key for products like wearable insulin pumps; AMT’s in-house testing and supply chains have accelerated such programs.

AMT makes scaling straightforward, from small trials to large output, while maintaining quality and compliance for entry into multiple markets.

Internal teams focus on commercialization while AMT covers build and compliance for quicker entry.

With AMT, costs drop, timelines compress, and scale grows—accelerating revenue and enabling expansion.

Engineering Collaboration: Prototyping and DFM

Early alignment brings AMT engineers into architecture, materials, and assembly planning—reducing risk and speeding progress.

Upfront Co-Engineering

AMT’s engineers bring lessons from ventilators and surgical tools to refine new designs, running checks to spot issues early and proposing cost-saving changes—a clear advantage in custom medical device development.

Rapid prototyping and iterative testing

Rapid prototyping at AMT tests ideas quickly; engineers build functional models, test, and iterate to reach final design faster and lower late-stage redesign risk.

Design for manufacturability (DFM)

DFM aims to streamline builds by reducing part count and easing assembly; consolidating parts into modules improves yields, lowers cost, and enables smoother scaling.

| Stage | AMT Role | Expected Benefit |

|---|---|---|

| Concept/Early Design | Architecture review, materials, risk analysis | Lower risk with a clearer roadmap |

| Prototype | 3D prints, functional and PCBA prototypes | Faster validation and regulatory data for submissions |

| Iteration | Performance testing, user trials, design tweaks | Improved reliability and fewer late revisions |

| DFM implementation | Part consolidation, tooling recommendations, assembly simplification | Lower unit cost, higher yield |

| Scale-up | Pilots, validations, supplier onboarding | Smoother transfer to volume production under a contract manufacturing partnership with AMT |

Problem-solving engineers plus prototypes, testing, and DFM raise readiness and trust in AMT for the long term.

Choosing a contract manufacturing partner in Singapore: what to look for

Selecting a good manufacturer is vital to product quality, regulatory success, and speed to market; Singapore offers global shipping, skilled talent, and strong compliance—compare carefully to preserve project value when choosing AMT or others.

Proven Certifications and History

Check ISO 13485 and ISO 9001 with 21 CFR Part 820 compliance; review quality manuals, CAPA, and DHRs; look for proof in respiratory care, telehealth, and disposable surgical tools before selecting a contract with AMT.

Facilities & Logistics

Examine cleanrooms, tooling, injection molding, PCBA, and automation; visit sites to confirm space and environmental monitoring; Singapore’s location enables fast ASEAN and global shipping—ideal for global launches.

Communication, IP protection and partnership models

Ensure secure project management and design handling; protect IP with controlled access and qualified suppliers; evaluate engineering support and supply continuity; confirm ability to scale across target markets.

| Area | What to check | Reason |

|---|---|---|

| Regulatory Compliance | ISO 13485, ISO 9001, 21 CFR Part 820, FDA-aligned QMS | Ensures market entry readiness and lowers regulatory risk |

| Technical | Cleanrooms, molding, PCBA, automation, tooling | Enables repeatable quality and scale |

| Domain Experience | Relevant case studies in key domains | Faster onboarding, better first-run yield |

| Logistics/Location | Ports proximity, regional channels, lead time | Reduces transit delays and inventory costs |

| Commercial/Legal | NDA/IP, flexible contracts, pricing | Asset protection with scalable terms |

| Communication & Culture | PM tools, reporting cadence, on-site audits | Improves transparency and long-term collaboration |

Gather references and visit facilities; run a pilot lot to test process/supply fit—diligence builds confidence for long-term partnership.

What’s Next: Trends Shaping Med Device CM

The future is moving toward personalization and faster, more digital workflows; Singapore and global manufacturers are adapting to patient-specific needs without major cost increases—requiring flexible tools, better data, and skilled teams.

Additive manufacturing enables patient-specific, small-batch runs for quicker, less wasteful care.

Automation and analytics detect issues early to support release; AMT leverages smart tech to sustain standards.

Focus areas include cardiac and orthopedic products, which demand very precise manufacturing—providers must grow services to keep pace.

Telehealth requires secure software and robust electronics; remote monitoring products highlight the need for close collaboration with manufacturing partners.

Manufacturers must combine automation with human skill for complex builds; those who choose wisely will excel in medtech by selecting the right projects.

The Bottom Line

Contract manufacturing of medical devices by AMT is a smart choice for OEMs focused on research and market expansion; AMT’s ISO 9001/13485 and 21 CFR Part 820 systems, plus cleanrooms and injection molding, speed up market entry while meeting strict compliance.

Projects like telehealth ventilators and single-use TURP electrodes prove the value of partnering with AMT—broad technical skills and assured quality—making outsourcing a strong option for growth across regions.

AMT focuses on early engineering collaboration, fast prototyping, and efficient procurement; for Singapore and global OEMs exploring outsourcing, amt – contract manufacturing of medical devices may be the key, adding capacity and ensuring regulatory readiness while saving time and money.